At LSPI, safety is our number one priority, and we are committed to caring for and protecting our environment, our communities, our partners, and each other. This year, we are proud to shed light on the outstanding safety milestones, achievements and recognitions that reflect the extent to which our safety culture is embedded in the core fabric of our organization. Maintaining an excellent safety record enables LSPI to ensure continuous and reliable production of DRA, allows us to recruit, develop, and retain the best employees in the industry, and it fosters a safety-first operational standard that extends into how we work with our customers.

LSPI Recognized by ISNetworld as a RAVS Plus Participant

In February 2021, LSPI completed and passed the ISNetworld (ISN) Review and Verification Services (RAVS) Plus Audit with a perfect score and no findings. ISNetworld is the main contractor management program our customers use to verify our HSE programs. Only 10% of ISN participants worldwide are recognized for their commitment to safety through this program. ISN RAVS certifies the extensiveness of a company’s written HSE programs and further audits the HSE management system to ensure the company is fully compliant with critical policies. ISN RAVS Plus differentiates LSPI from our competitors by confirming that our organization has a robust HSE management system for current and potential customers. This audit involved five LSPI Field Service Representatives (FSRs) taking an extensive test, an evaluation of more than 25 written HSE programs, submission of training records and an interview with LSPI’s HSE Global Director and HSE Technician. We are proud of our team members who participated in the ISNetworld RAVS Plus Audit and helped LSPI achieve this designation.

In February 2021, LSPI completed and passed the ISNetworld (ISN) Review and Verification Services (RAVS) Plus Audit with a perfect score and no findings. ISNetworld is the main contractor management program our customers use to verify our HSE programs. Only 10% of ISN participants worldwide are recognized for their commitment to safety through this program. ISN RAVS certifies the extensiveness of a company’s written HSE programs and further audits the HSE management system to ensure the company is fully compliant with critical policies. ISN RAVS Plus differentiates LSPI from our competitors by confirming that our organization has a robust HSE management system for current and potential customers. This audit involved five LSPI Field Service Representatives (FSRs) taking an extensive test, an evaluation of more than 25 written HSE programs, submission of training records and an interview with LSPI’s HSE Global Director and HSE Technician. We are proud of our team members who participated in the ISNetworld RAVS Plus Audit and helped LSPI achieve this designation.

Plant Safety: Liberty and Bryan Plants, 1 Year Without Recordable Incidents

LSPI’s Liberty plant in Chickasha, Oklahoma, and both Bryan plants have all completed one year without a recordable incident. These milestones are a testament to LSPI’s commitment to safety and to the safety of those around them. Our employees at both the Liberty and Bryan plants have put a tremendous amount of effort into hazard recognition and mitigation while providing essential services to our organization and customers. Our plant employees have continuously fostered a safety-focused culture and maintained a safe work environment by conducting their work in accordance with principles that promote safety.

LSPI’s plant employees have maintained a safe work environment by driving employee engagement with an employee-led Frontline Safety Team, which champions safety initiatives throughout the plants.

LSPI’s Flow Improver Research, Science, and Technology (FIRST) Center: 17 Years Without Recordable Incidents

In September 2021, LSPI’s Flow Improver Research, Science, and Technology (FIRST) Center in Ponca City, Oklahoma achieved a working safely goal of zero recordables since 2004!

In September 2021, LSPI’s Flow Improver Research, Science, and Technology (FIRST) Center in Ponca City, Oklahoma achieved a working safely goal of zero recordables since 2004!

This outstanding milestone demonstrates the personal responsibility to safety that every member of our research and development team brings for themselves and their colleagues in their daily choices.

Fostering a successful safety culture can be attributed to a continuous focus to personal safety and the safety of others, supported by our safety leadership, robust training and the comprehensive safety rules, procedures, and guidelines in place to ensure the safest possible working conditions.

LSP Transport (LSPT) Reaches 10 Million Safe Miles Driven!

As of August 8, 2021, we are proud to share that LSPI’s in-house private fleet, LSP Transport (LSPT), reached 10 million safe miles driven, distributed across our different terminals in Bryan, Texas, Stanton, North Dakota, Chickasha, Oklahoma, Granite City, Illinois, and San Angelo, Texas.

As of August 8, 2021, we are proud to share that LSPI’s in-house private fleet, LSP Transport (LSPT), reached 10 million safe miles driven, distributed across our different terminals in Bryan, Texas, Stanton, North Dakota, Chickasha, Oklahoma, Granite City, Illinois, and San Angelo, Texas.

With more than 20 years of experience in the chemical transportation industry, LSPT became a wholly owned subsidiary of LSPI in 2015 and is dedicated to safely delivering LSPI’s products to customer sites.

Reaching 10 million miles driven without a preventable DOT accident reflects the level of commitment to excellence and the high safety standards upheld by every member of the organization, from our drivers, maintenance teams and dispatch planners, to our safety, administrative and management groups. LSPI’s unique and robust inhouse transportation enhances our logistics outreach, allowing additional flexibility in business operations to ensure reliability and uptime.

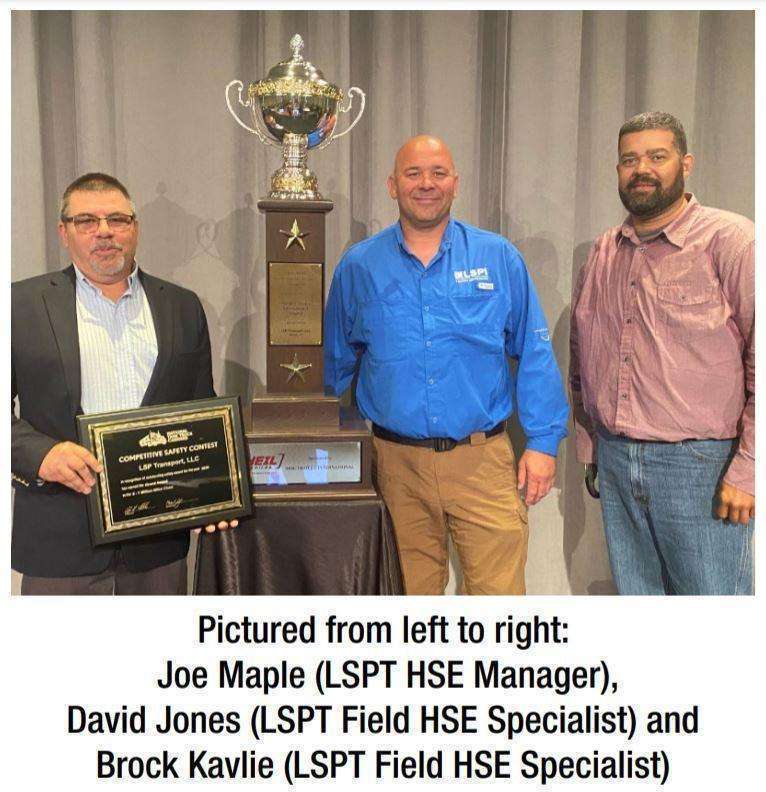

LSP Transport, LLC (LSPT) Crowned North American Safety Champion

National Tank Truck Carriers named LSP Transport, LLC (LSPT) the North American Safety Champion of the Sutherland division. NTTC’s annual award recognizes tank truck operations in North America with the best safety programs and records each year and represent the gold standard for safety in the tank truck industry.

The NTTC is the only national organization that specifically focuses on the tank truck industry. The North American Safety Contest, which awards the Heil Trophy, recognizes North American tank truck operations that excel in nine different categories.

Joe Maple, LSPT HSE Manager, accepted the Heil Trophy stating “these awards don’t happen without a lot of work behind the scenes. We’ve got a great company…starting at the top. The most important to our success are our drivers –who buy into our culture, do the best they can to go home the same way they came to work…and take the extra time to do what needs to be done to make sure we do it safely. Without them, there’s no way we could make this happen.”

Joe Maple, LSPT HSE Manager, accepted the Heil Trophy stating “these awards don’t happen without a lot of work behind the scenes. We’ve got a great company…starting at the top. The most important to our success are our drivers –who buy into our culture, do the best they can to go home the same way they came to work…and take the extra time to do what needs to be done to make sure we do it safely. Without them, there’s no way we could make this happen.”

Winners are determined by their safety records, safety and preventive maintenance programs, personnel safety programs and record, and contributions to tank truck industry and general highway safety causes. LSPT secured its trophy with a frequency of 0.344 accidents per million miles in the 5-7 million miles class of the Competitive Safety Contest, and won a Grand Award in the Personnel Safety Contest.

LSPI’s recent safety achievements, milestones and recognitions are a testament to the safety culture that permeates all aspects of the organization. We congratulate our HSE group, manufacturing personnel, field service representatives, LSPT team and research and development employees for conducting their work with tenacity and exemplary professionalism, while remaining focused on their safety as well as the safety of others. We are proud of our employees at all levels who share the attitudes, beliefs and safe work practices that maintain safety excellence at the center of all that we do.